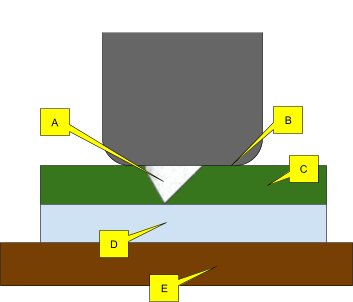

How the cartridge works

The blade (A) projects out of the cartridge nose (B). A pressure is applied to the cartridge nose (B) so that the cartridge nose is in contact with the top surface of the vinyl. This means blade will always cut a consistent depth relative to the top surface.

A: Blade

B: Cartridge nose

C: Vinyl

D: Vinyl backing

E: Base board

Setting the blade height

When cutting vinyl, setting the correct blade height is especially important. If you do not set the blade height correctly, you can end up cutting too far through your material, or not far enough. To set the blade height, follow the steps below.

Insert the blade you wish to use into the vinyl cartridge

Loosen the gold locking ring on the vinyl cartridge

Rotate the top part of the cartridge assembly until the blade extends from the cartridge the correct amount

Tighten the gold locking ring to fix the blade height.

|

|

IMPORTANT: The blade should be set to extend from the cartridge system the same distance as the thickness of the material you wish to cut.

|

For example, if you are cutting a self-adhesive vinyl then you will need to ensure the blade (A) is only cutting through the top layer ie the vinyl (C), and not the backing paper (D).

A: Blade

B: Cartridge nose

C: Vinyl

D: Vinyl backing

E: Base board

Inspection jig

We have included a blade height jig which will allow you to clearly see how far the blade extends from the cartridge.

To use the jig, hold the cartridge against the edge of the flat face. This will allow you to clearly see how far the blade extends from the cartridge and adjust, as necessary.

How to test

We would strongly recommend testing the blade height on a scrap piece of vinyl before committing to your project.

Once the blade height has been set, manually drag the cartridge over the scrap vinyl piece:

How to inspect the result

Here are some examples of good and bad results:

X: Blade has not cut deep enough. The vinyl has not been cut all the way through, just scratched.

Y: Blade has cut too deep. Both the vinyl and the backing paper have been cut.

Z: Blade at perfect height. Only the vinyl has been cut, the backing paper has not been cut. The vinyl can be peeled from the backing paper.

Final checks

|

|

Make sure that the golden lock ring is tight before loading into CNC Stylus. If it comes loose, then the blade height may change mid job!

|