Understanding the difference between ER & OZ collets.

< Previous | List | Next >

General

We offer spindles to cater for 2 different types of collet.

-

OZ series (ISO 10897)

-

ER series (ISO 15488)

Which is best for you

The OZ series is the cheaper solution, but the ER collet offers benefits which include:

If you already have some collets in your tools, this may also be a deciding factor.

Different collets for different spindles

|

Spindle

|

Collet type

|

Part Number

|

|

Yeti Tool SC0 110V

|

OZ

|

20792

|

|

Yeti Tool SC1 110V

|

ER

|

20794

|

|

Yeti Tool SC1 230V

|

ER

|

20795

|

|

AMB 110V

|

OZ

|

20189

|

|

AMB 230V

|

OZ

|

20098

|

|

AMB Precision 230V

|

ER

|

20190

|

What makes the ER collet different?

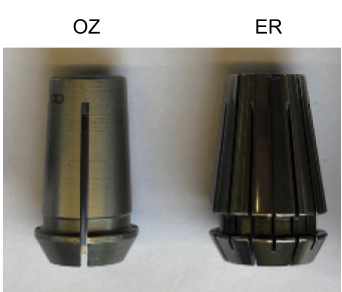

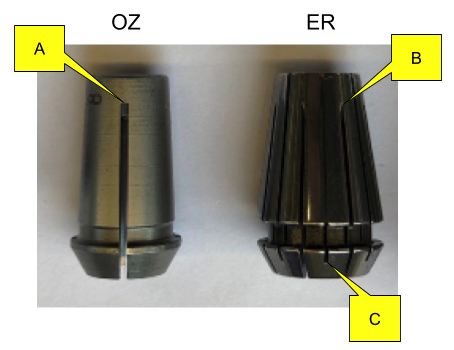

Both collets have slots in them to allow the collet to compress when the nut is tightened, gripping the shank of the tool.

However, the positions of the slots vary. Note how the OZ slots only come from one end - they all start from the top (A) - whereas the ER slots start at both top (B) and bottom (C).

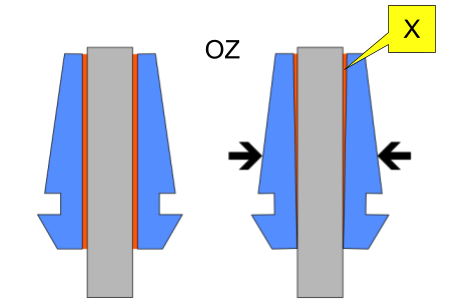

The OZ slots only extend from the top, so when the OZ collet is compressed, the collet only folds inward only at the bottom. This makes the clamp force uneven along the length of the tool, weakest at the back (X). This is tangential clamping.

The ER slots extend from both the top and the bottom, so when the ER collet nut is tightened, the collet compresses evenly along the length of the tool shank. We call this even clamping.

Tangential clamping (OZ) does not perform as well as even clamping (ER) in various different areas of operation.

Advantages of the ER series

-

ER is less prone to jamming during tool change.

-

ER reduces wear, vibration and noise during operation.

-

ER has an improved clamping force on the tool.

-

ER collet allows for a total clamping range.

< Previous | List | Next >