Despite its small stature and affordability, SmartBench doesn’t compromise on performance. Read on to learn how SmartBench is perfect for production environments.

< Previous | List | Next >

Feeds and speeds

SmartBench needs to be treated slightly differently to other CNC machines, and there are many different factors that can affect the feeds and speeds you should use.

Click here to open our conservative guide about feeds and speeds, which should be taken as a starting point.

An example of feed rates

For an idea of feed rates, consider this scenario:

Job specifications

|

|

Tool

|

8mm spiral downcut

|

|

Material

|

Birch plywood (2440 x 1220 x 12mm)

|

Recommended strategy

|

|

Passes and step down

|

4mm deep per pass, x3 passes

|

|

Feed rate

|

4000 mm/min

|

|

Spindle speed

|

23,000 RPM

|

Quality and reliability

Each SmartBench is assembled, calibrated, put through a thorough multi-point QC procedure, and then a 6 hour test before leaving the factory.

We have two SmartBenches that are a critical part of our own SmartBench production line. They work 5 days a week, 9 hours a day.

Check out this video to learn more:

Continuous monitoring

SmartBench’s continuous self-monitoring helps you to keep track of and optimize its performance; key to minimising downtime!

Self-monitoring features include:

-

automatic reminders to help you to carry out important maintenance tasks at regular intervals;

-

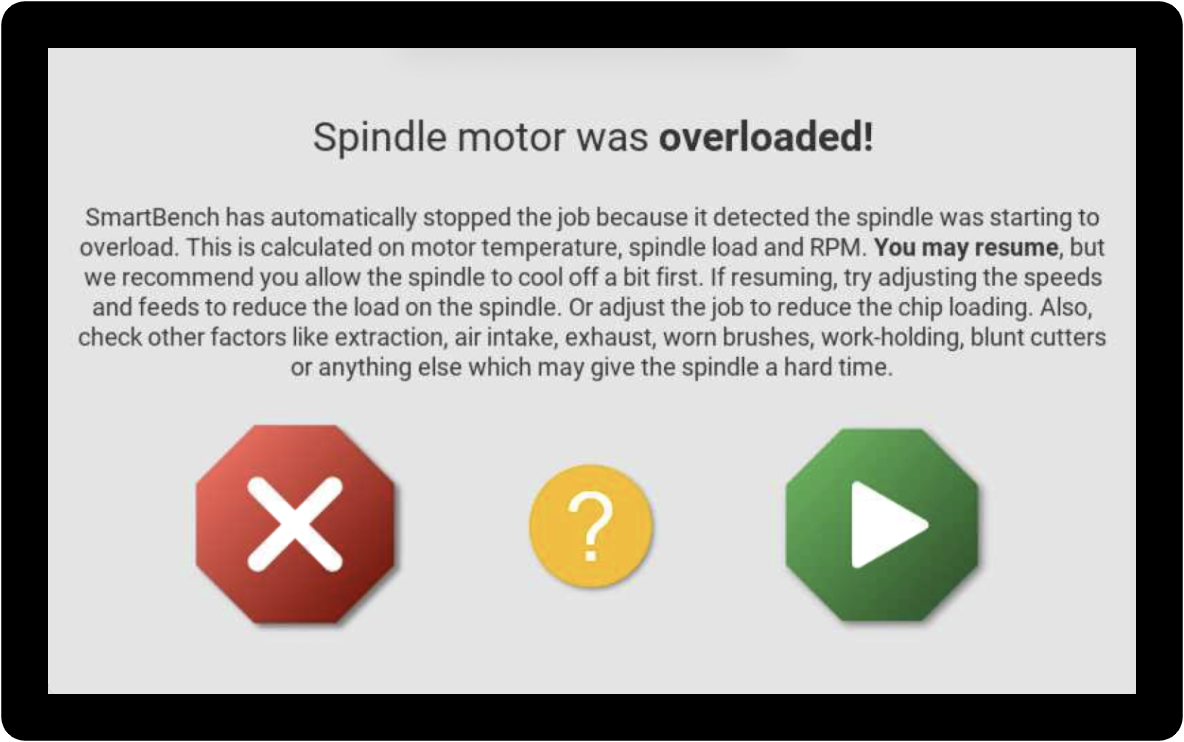

(Precision and PrecisionPro models) spindle overload protection, which auto-pauses the job whenever SmartBench detects that the stress on the spindle is too high.

|

|

We’re always aiming to make SmartBench even smarter, so expect more self-monitoring features in the future, downloadable via free Console software updates.

|

Tools to assist the operator

We know that turnaround time is important, so SmartBench is packed full of features to help the operator:

< Previous | List | Next >