This article is an introduction to CNC routing cutters.

List | Next >

Introduction

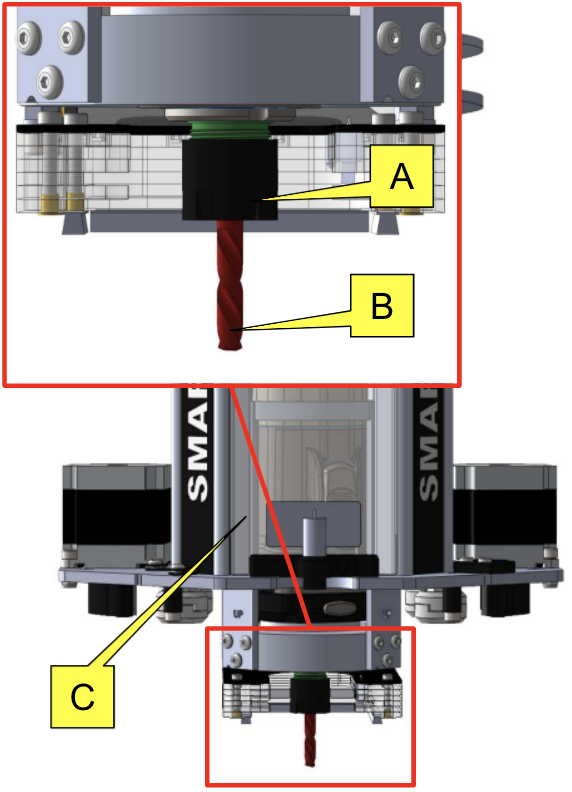

Routing is a process where rotary cutters typically remove material using a sideways action. In SmartBench, the cutter is mounted in the spindle motor, mounted in the Z Head.

A: Spindle motor

B: Cutter

C: Z Head

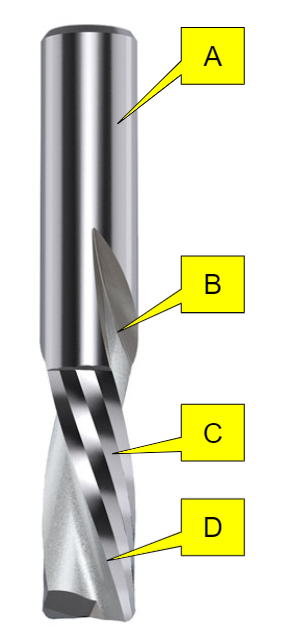

Router cutter basic elements

A: Shank - this is where the spindle holds the cutter.

B: Flute - for evacuating chips (cut material).

C: Body - this has the cutting edges and flutes of the cutter.

D: Cutting edge - this cuts through the stock material.

Key features

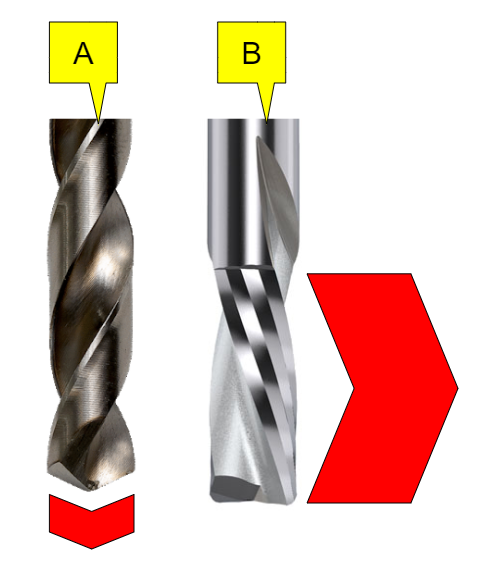

To illustrate some of the features of router cutters, let’s compare them to a more commonly known tool: the drill bit.

|

|

NEVER use a drill bit in a router spindle!

|

Cut process & loading

As a process, routing is very different from drilling. Drilling only cuts at the end face of the drill bit to create holes during a downwards movement, whereas the router cutter needs to cut along the whole side face of the tool to create slots during a sideways movement.

In the following image, the red arrows indicate the cutting directions and areas.

A: Drill bit

B: Router bit

Balance

To manage the higher loading on the tool, the router bit needs to spin an order of magnitude faster.

Here is a chart of typical revolutions per minute (RPMs) for each type of bit:

|

6mm cutter into timber

|

Typical RPMs

|

|

Drill

|

2,000

|

|

Router

|

20,000

|

Because of this very high RPM rate, router blades must be balanced to a very high degree.

|

|

Never use a cheap unbalanced cutter in a router spindle. An unbalanced bit in a high speed router cutter will deform to dangerous limits. At best, cut performance will be very bad.

Never use a drill bit in a router spindle for the same reason. Typical drill bits are not balanced (since they are designed for low RPMs only).

|

Compatibility with SmartBench

The largest cutter shank diameter (A) SmartBench can use is 10 mm for ER16 collets, or 8 mm for OZ collets.

The hole in the dust shoe will accept a cutter body diameter (B) of up to 26 mm (1 inch).

You can use any third party router bits with SmartBench as long as your shank diameter and body diameter do not exceed the maximum requirements.

Click here to see our wide range of compatible cutters from CMT Orange Tools.

List | Next >