This article discusses what a compression cutter is and how to use them correctly with SmartBench.

< Previous | List | >

What is a compression cutter

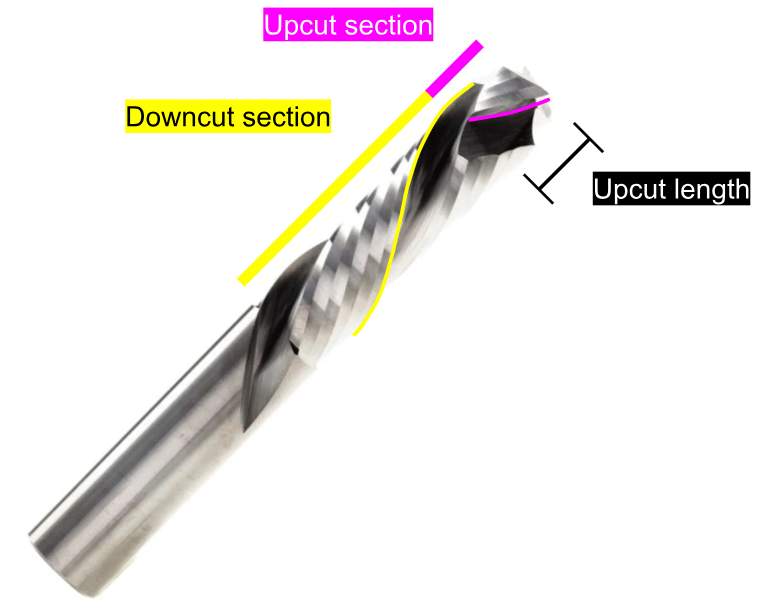

A compression cutter combines upcut and downcut cutting edges.

This is done so that the cutter contacts the top face of your material with a down cutter and the bottom face of your material with an up cutter.

This typically produces good top face and bottom face finishes, unlike an up or down cutter which only cuts one face cleanly.

Where to use a compression cutter

Compression cutters are widely used in machining where both top face and bottom face finishes are important.

With SmartBench, compression cutters are used in various timber products such as Plywood, MDF, MFC, Hardwoods and more.

Correct strategy with compression cutters

Using compression cutters requires a unique approach compared to other cutters.

In order to take advantage of a compression cutter’s combined flute types, you must use a stepdown greater than the length of your cutter’s upcut length.

Otherwise, the downcut section of the tool will not reach the top surface of your material, and you will experience tearout

Ideal upcut length

Compression tools are available with different upcut lengths.

Typically, a shorter upcut portion is best for SmartBench. This is particularly true for hard materials such as hardwoods and MFC

This is because a longer upcut portion requires a larger stepdown.

Which requires a slow feedrate, potentially causing burning in your material.

As a result, we typically favour shallow upcut sections (e.g 4 mm and below)

How to add lead ins to your design

To prevent any issues with your compression cutter plunging into your workpiece we recommend the use of lead ins before the cut itself, this article here shows how to

add lead ins on Vectric< Previous | List | >