This article explains what the BigFoot dust shoe is and why you might need it.

< | List | Next >

Overview

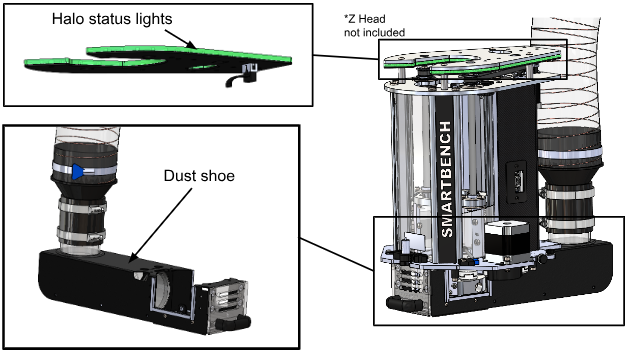

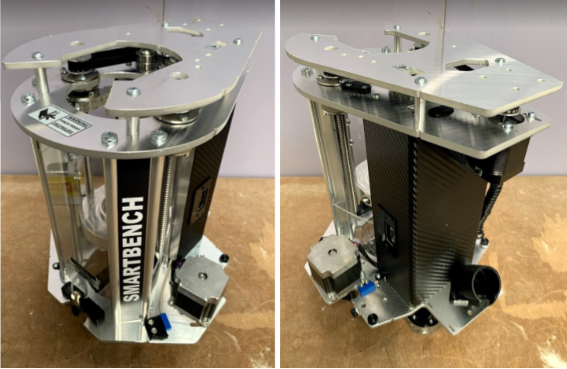

The BigFoot system replaces the standard dust shoe on SmartBench. It allows SmartBench to be used with an industrial extraction system, supporting a 100mm diameter hose and bigger bags for uninterrupted cutting. It is suited to static installations where SmartBench is used for high throughput.

The BigFoot dust shoe comes as standard on the PrecisionPro X, and is also available as an upgrade for other models of SmartBench. Please see our section below on compatibility to check that it fits your version.

What does it do?

BigFoot dust shoe

BigFoot can be connected to a 63 mm (2.5") or 100 mm (4”) pipe, which is standard ducting size for industrial dust extractors. This enables the following benefits:

-

Improved waste clearance by enabling a higher air-flow: Large dust extractors have a higher flow rate than shop vacuums (which use a 38 mm hose)

-

Allows collection of larger chips without blocking: hose is much less likely to block than a shop vac’s 38 mm hose when dealing with larger debris such as plywood strings

-

Reduces the frequency of bag changes: the 63 or 100 mm system means that the user can capitalise on the larger capacity dust bag that a static dust extractor has and save time on changing bags. It is also common to use a cyclone separator with this type of system which further increases capacity

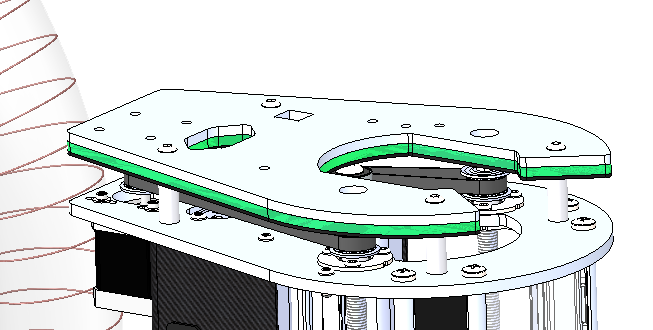

Halo status lighting

BigFoot will come with an extra status lighting PCB which will sit under the Z Head cover plate so it is visible from all sides of the machine. This will help operators and managers keep track of the machines’ status.

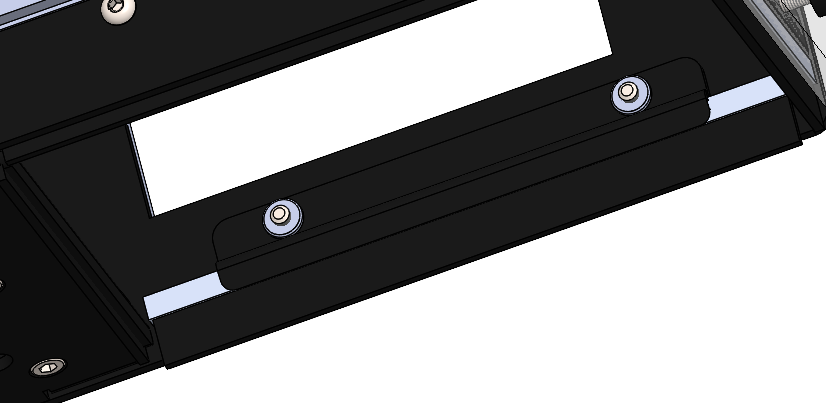

Replaceable brush strips

The 3 brush strips on BigFoot create a seal against the workpiece. These are replaceable as a wear item.

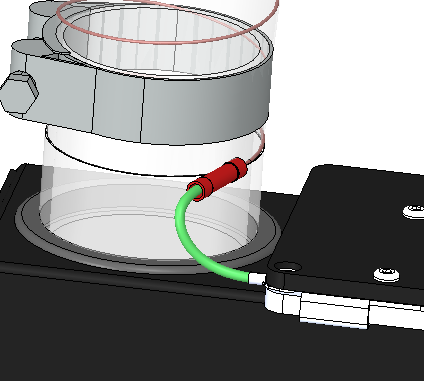

Built in static handling

The supplied flexible hose has a conductive winding which connects to your Z Head and an earthing point on your extraction ducting to discharge static electricity build up.

Tool/status lighting

The dust shoe itself has status LEDs which also serve to illuminate the cutting area.

Quick attach door

BigFoot has a magnetic door which is quick and easy to remove for Z datum probing

The four magnets have a 4.8 kg holding capacity to keep the door secure when cutting.

Extraction - Minimum requirements

For BigFoot to work effectively, it must run in the following system:

-

Minimum extractor inlet: ø 100 mm

-

Minimum extractor capability: 1,000 m³/hr

-

Piping from the extractor to the final flexible section must be

-

rigid,

-

smooth bore,

-

Ø 100 mm

-

The final length of the flexible hose running from the rigid piping section to BigFoot must not exceed 3 m.

-

The diameter of the flexible hose must be either 63 mm or 100 mm (see section below for information on pros and cons)

-

The flexible hose must be adequately strain relieved to avoid excessive loading onto SmartBench’s ZHead. This may require the installation of further suspension devices.

-

After extraction hose installation, SmartBench should be driven around a full range of movement to ensure that the flexible hose does not strangle the Z Head in any way.

Choice of flexible hose diameter

There are two potential flexible hose diameters you can use to run BigFoot:

-

100 mm hose: allows for greater air flow with lower pressure this is the setup that BigFoot ships with as it is the most compatible with common extractors, and suits most applications.

-

63 mm hose: will increase the pressure, but lower the airflow. This may suit applications with heavier particles. This is with the caveat that the extractor you are using must be powerful enough to maintain the velocity of air through the smaller 63 mm hose diameter.

Compatibility

-

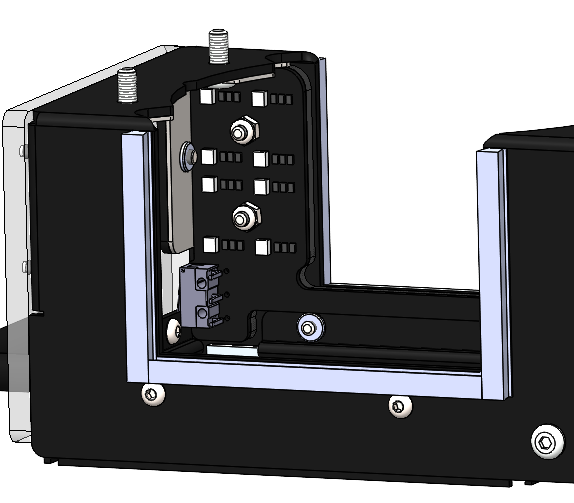

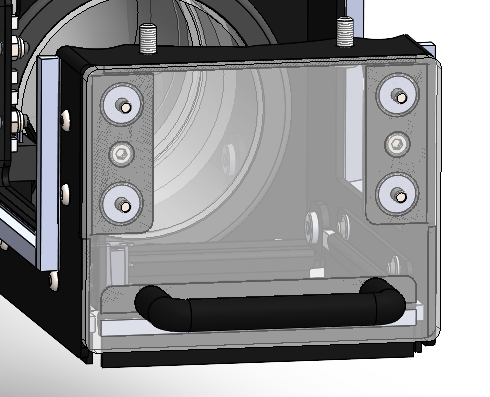

Compatible with Z head 2B onwards which looks like the one below. (SmartBench V1.2 onwards) - Please check this page for further compatibility information

-

No compatibility issues with other sub assemblies of any version.

< | List | Next >