During cutting you should monitor and adjust as necessary.

|

|

If you are trying something new (e.g. a new material or cutter) you can always cut a test piece first on some scrap material, and try adjusting feeds and speeds throughout the test.

|

What to look out for

Make chips, not dust

When you are honing your feeds and speeds, always look to make chips, not dust. Chips help to take heat away from the stock material, thus increasing tool life and finished edge quality.

Dust indicates that the cutter is not moving fast enough through the material, allowing the cutter blades to chop the chips into dust.

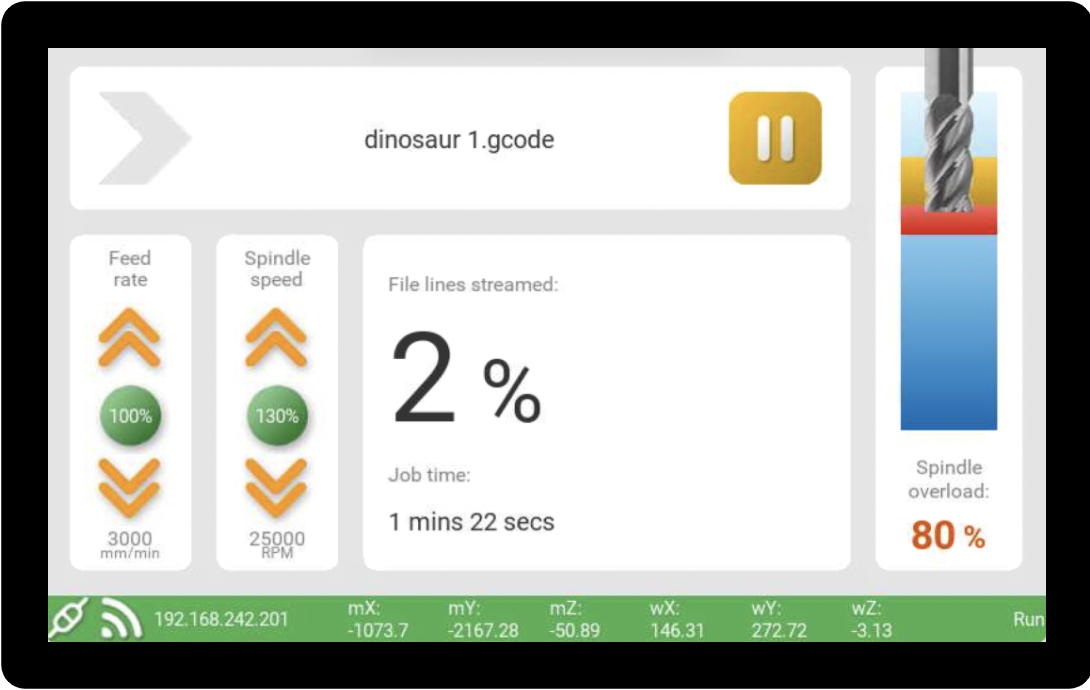

Monitor overload

If you have a PrecisionPro + or PrecisionPro X model of SmartBench, you may see the spindle overload begin to increase on the console, normally starting at 20%. If it gets beyond that, it’s definitely time to adjust feeds and speeds!

Click here to learn how to adjust your feeds and speeds during a job

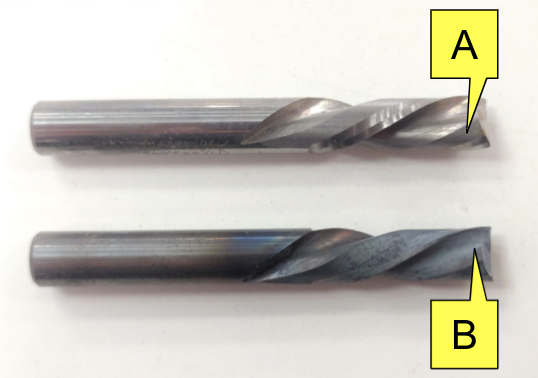

Check for overheating on the tool or stock material

Signs of overheating give you an indication of tool damage, or incorrect feeds and speeds. This means your cutter is rubbing rather than cutting. Again, this is an indicator that the cutter is not moving quickly enough through the material.

A: Edge without signs of overheating.

B: Edge with signs of overheating.

Blunt cutters

You should always check the condition of your cutter to ensure it is sharp and undamaged. Otherwise you might be trying to get the right feed and speed, when you should actually just change your cutter.

Click here to learn more about how to check your cutter.

A: Cutter in original good condition.

B: Cutter has been discoloured due to overheating.

How to adjust feeds and speeds during a job?

SmartBench gives you the ability to adjust your feeds and speeds at any time during the job. These can be changed in 5% increments to allow for fine adjustment.

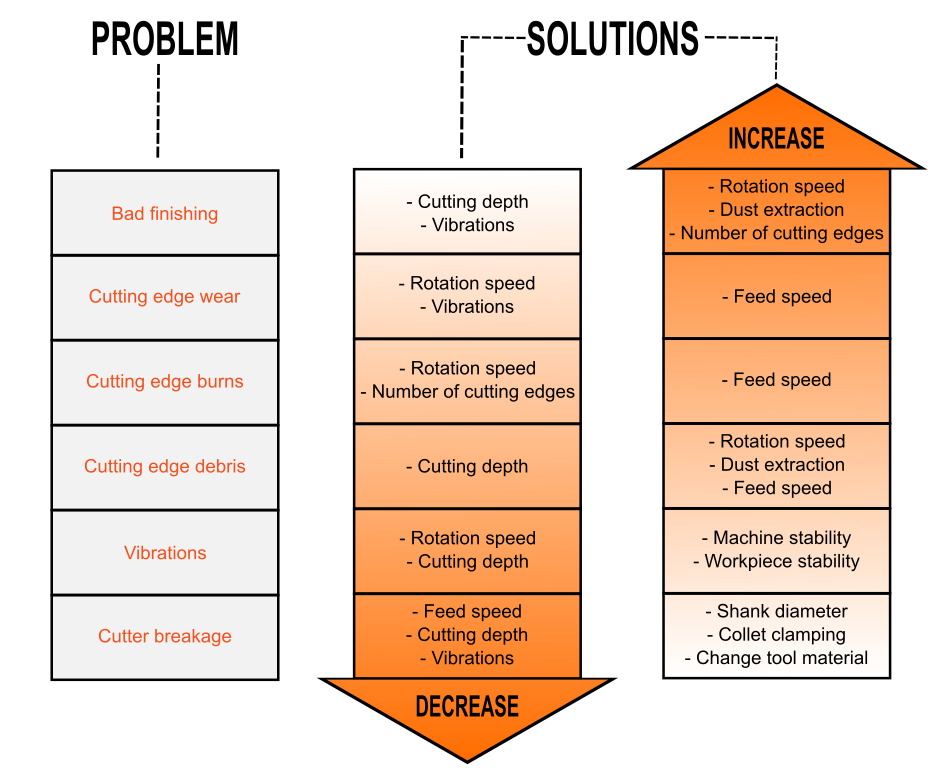

Tips on problem solving

Here is a problem solving map to help you if you start to have issues.

Image credit: CMT Orange tools

< Previous | List | Next >