This article explains the terms we use to describe different aspects of cutter performance

< Previous | List |

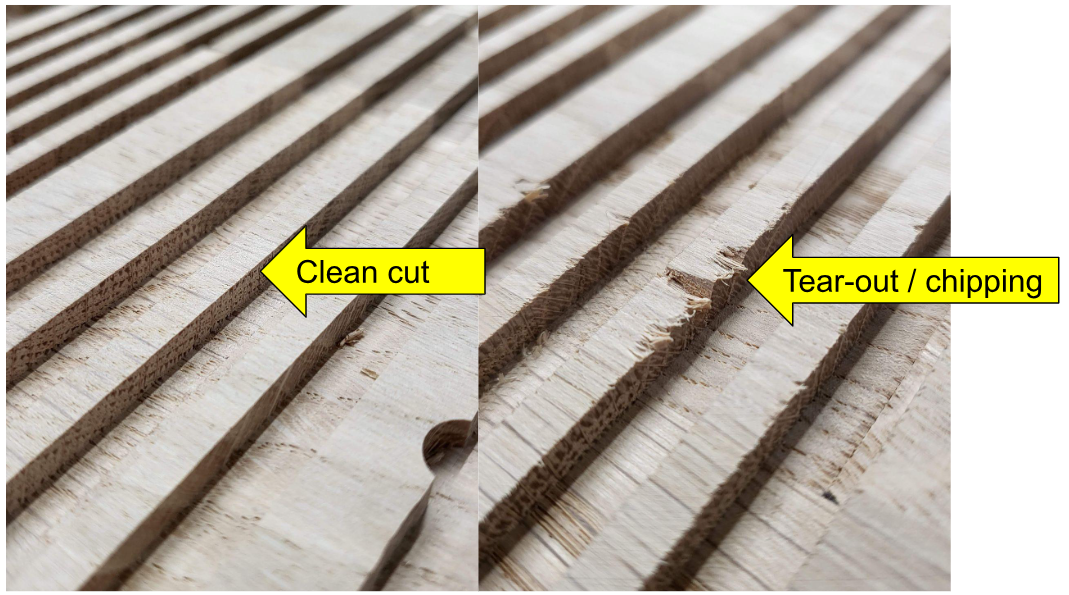

Top face finish

This refers to the condition of the top face of the stock, at the cut edge. The image below illustrates a good and bad top face edge when using up and down cuts.

A cutter that typically performs well at this is: Downcut

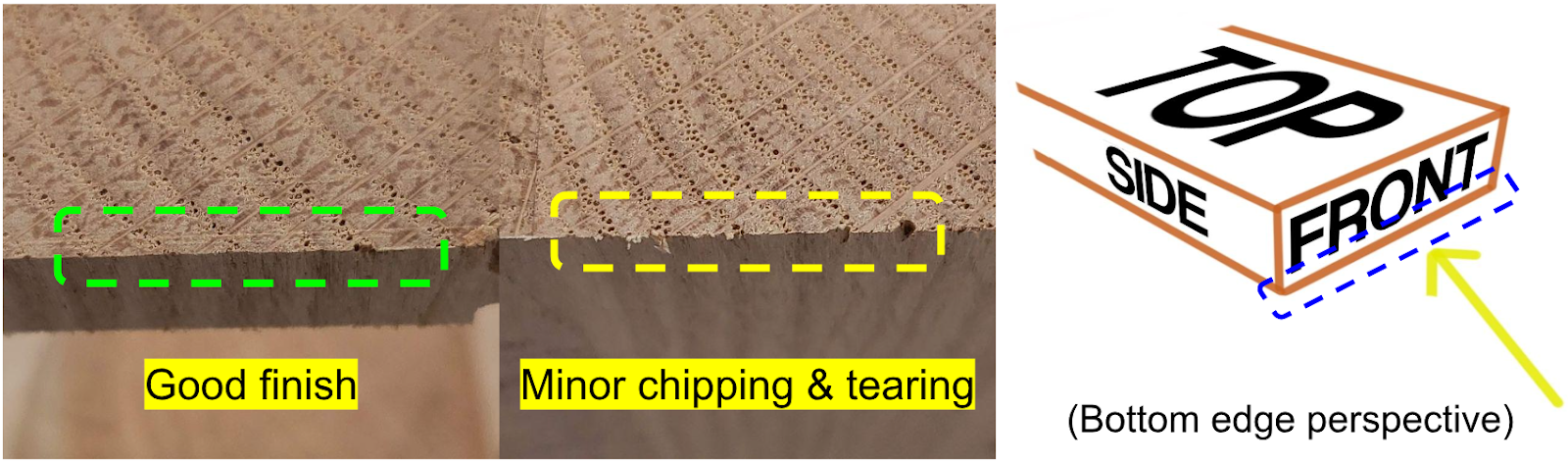

Bottom face finish

This refers to the condition of the bottom face of a cut feature when cutting through the full thickness of your material. See comparison below

A cutter that typically performs well at this is: Upcut

Productivity

Productivity is reference to how quickly a cutter can comfortably remove material i.e. a more productive cutter will be able to clear a large area of material more quickly.

A cutter that typically performs well at this is: Straight

Ease of use

Some cutters are happy at a range of feeds and speeds while other cutters can be very sensitive. We consider a cutter to have a high ease of use if it performs well across a wide range of feeds and speeds.

A cutter that typically performs well at this is: Straight

First pass accuracy

Some cutters produce more accurate parts on their first pass than others.

If accuracy is key to your cut, incorporate a finishing pass into your strategy. This is standard practice for most CNC operations. See how to add a finishing pass here.

A cutter that typically performs well at this is: Upcut

< Previous | List |